Information Sheet #12 - Preventive Maintenance of Electric Motors and Benefits

1.0 Introduction:

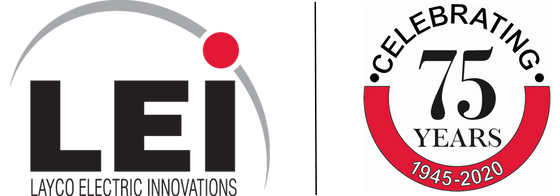

While most electric motors deployed in industry and commerce are designed and manufactured to provide drive for long periods with minimal maintenance, they are also a key component of the equipment and failure can result in significant disruption both life and economically critical. The best solution for eliminating unplanned shutdown of equipment due to motor failure is to have in place a Preventive Maintenance (PM) program. Along side PM programs there is also Predictive Maintenance (PdM). A PdM is scheduled on the results of PM programs and forecasts the length of time between failure of various structures and components within an electric motor.

2.0 The Benefits of Preventive Maintenance Programs for Electric Motors:

Operators and facility managers know the downside of unscheduled shut downs due to equipment failure. While most electric motors are manufactured to provide a high degree of reliable continuous operation, like any other piece of rotating equipment they have components subject to wear over time. Planned, or preventive maintenance (PM) programs look to regularly check on the state of an electric motor at a frequency that identifies issues before they become a problem. The majority of facilities and processes that heavily rely on electric motors to operate have the following benefits when implementing PM programs.

Also in Information Sheet Blog

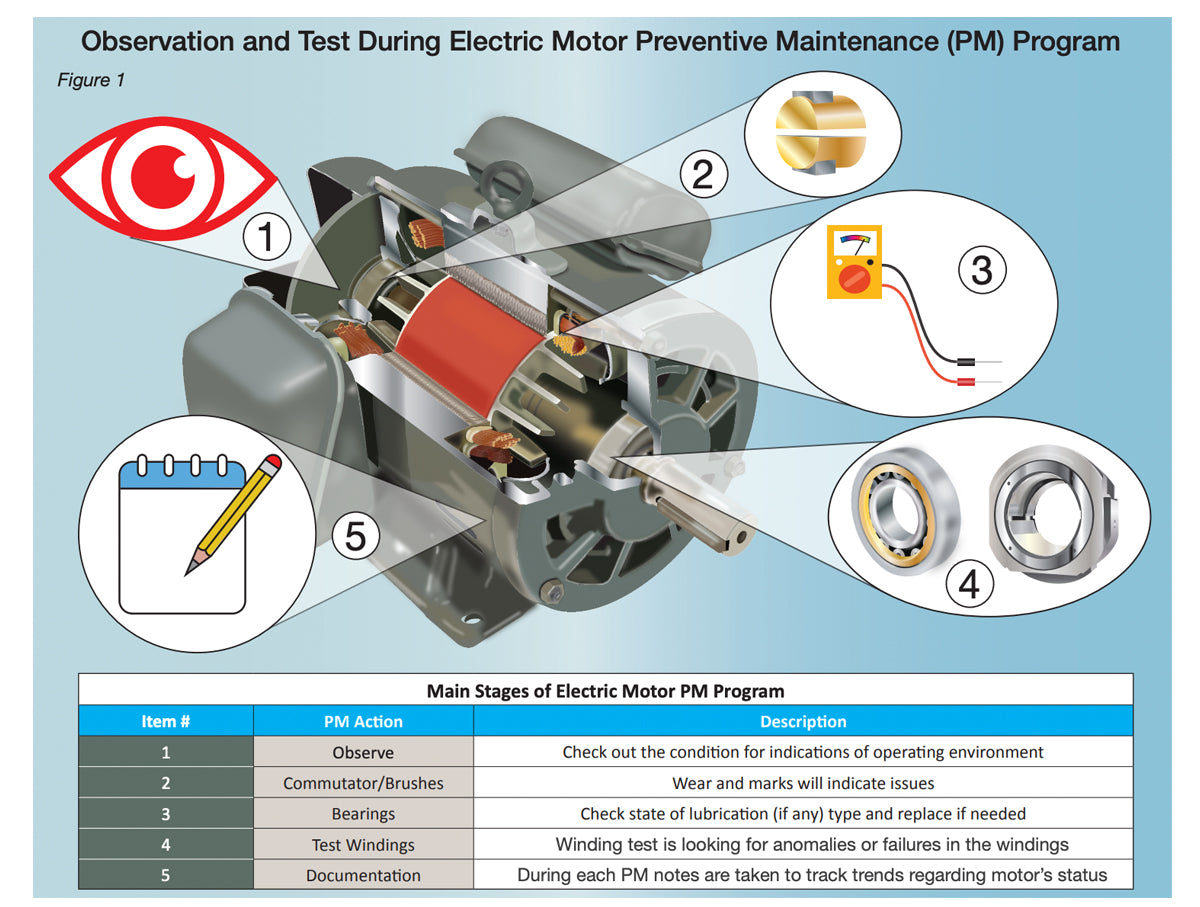

Information Sheet #13 – NEMA Motor Repair, Best Practice & Definitions

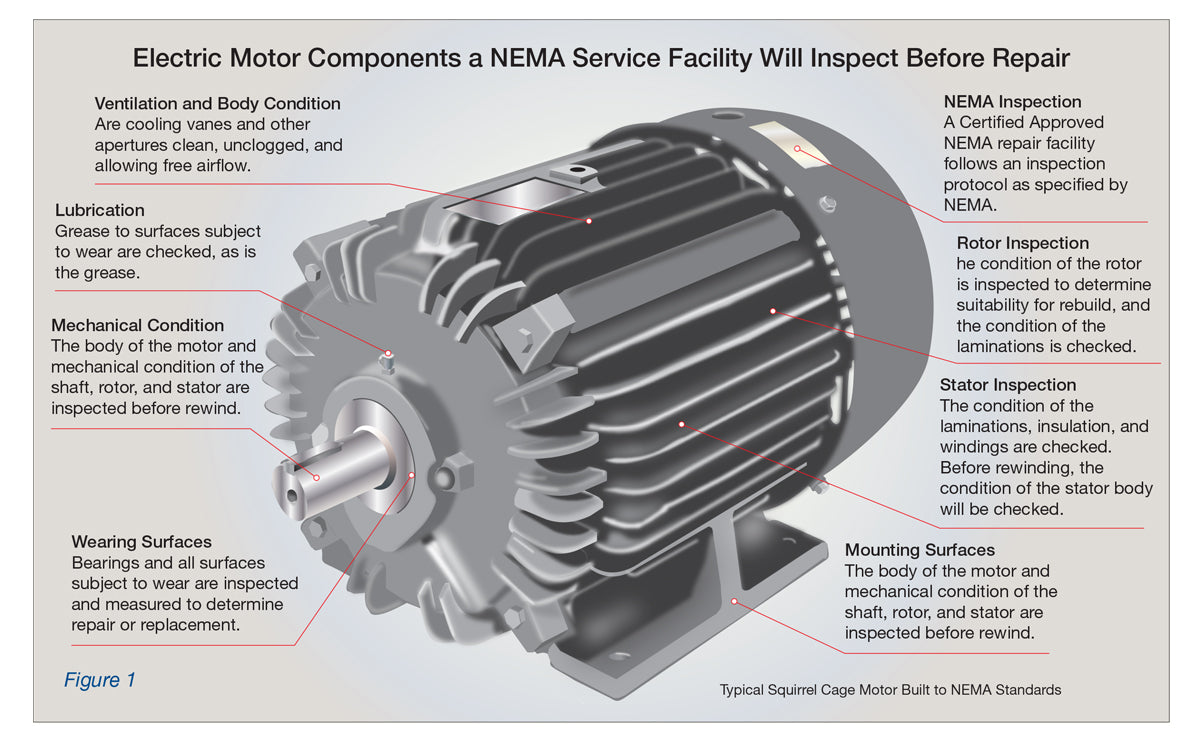

Information Sheet #11 - Brownouts & The Adverse Effect On Electric Induction Motors.

This information sheet discusses the adverse effect brownouts have on electric motors, particularly induction motors and how to manage them.